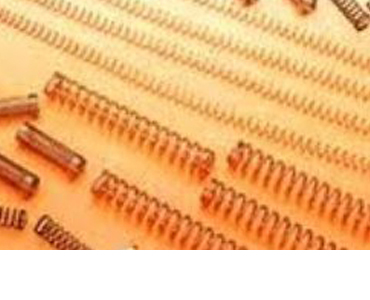

Compression Springs

We have in store for our customers a wide range of Compression Springs, which are used to resist compressive forces. These springs are manufactured using CNC spring machines and find applications in manufacturing electronic components, electrical switches, mechanical & oil seals, automobile components, umbrellas, hydraulic and pneumatic components.

Compression Springs: Versatile, Reliable, and Customizable

Welcome to Santosh Industrial Springs, We are leading Compression Springs , manufacturers, suppliers and exporters located in Andheri, Mumbai, Maharashtra India. Compression springs are fundamental mechanical devices used to store and release energy in various applications. At their core, these springs are designed to absorb force or load when compressed and return to their original position when the force is removed, making them essential components across multiple industries.

Versatility in Design and Functionality

Compression springs come in various shapes, sizes, and materials to suit a wide array of applications. They can be conical, cylindrical, or hourglass-shaped, and their versatility allows them to be used in everything from small household appliances to heavy industrial machinery.

Materials and Durability

Manufactured from materials such as high-carbon steel, stainless steel, or alloys, these springs are built to withstand substantial compressive forces repeatedly without losing their elasticity. The choice of material depends on factors like environmental conditions, load requirements, and corrosion resistance.

Customization for Specific Needs

One of the significant advantages of compression springs is their customizability. Engineers can tailor these springs to precise specifications regarding load capacities, dimensions, and functional requirements. This customization ensures they fit seamlessly into various systems and applications.

Applications Across Industries

Compression springs are ubiquitous and serve critical functions in numerous sectors. From automotive suspensions and aerospace mechanisms to medical devices and electronic components, their ability to provide consistent force makes them indispensable in many critical applications.

Quality and Reliability

Quality control measures are paramount in the manufacturing of compression springs. Rigorous testing and inspection ensure compliance with stringent quality standards, guaranteeing reliability, durability, and consistent performance in diverse environments.

Expert Guidance and Support

For industries seeking specific compression spring solutions, expert consultation and support are crucial. Partnering with a trusted manufacturer ensures proper guidance in selecting the right type of compression spring for specific applications.

In conclusion, compression springs play a vital role in various industries due to their versatility, durability, and ability to provide reliable force. For tailored compression springs meeting precise requirements, partnering with experienced manufacturers ensures optimal performance and reliability.